Passivhaus in Practice...

/The Institute of Departmental Regenerative Medicine (IDRM) is a state-of-the-art research building created for the University of Oxford with the aim of developing treatments for degenerative diseases, promoting multidisciplinary expertise and building strong collaborations with other world leading institutes. To meet the client’s sustainability ambitions, a key driver was that the building should be designed using Passivhaus methodology to offer a more accurate prediction of energy use during operation and achieve better user comfort.

Now that the IDRM project has achieved Practical Completion, we are taking the opportunity to reflect on some of the lessons learned and project successes. One such success has been the integration of innovative Passivhaus design principles, improving the building performance and reducing in-use energy demand combining innovative systems with practical detailing to achieve affordable, effective inclusion of some of the key benefits.

Passivhaus Principles

From the outset of the project the various options available to the client were discussed to achieve their sustainability goals. In the case of the £26m IDRM Building for the University of Oxford a collaborative dynamic was established between the University, design team, main contractor and supply chain meaning we were able to identify certain key drivers in achieving a highly functional and effective building with careful consideration and application of the following Passivhaus principles.

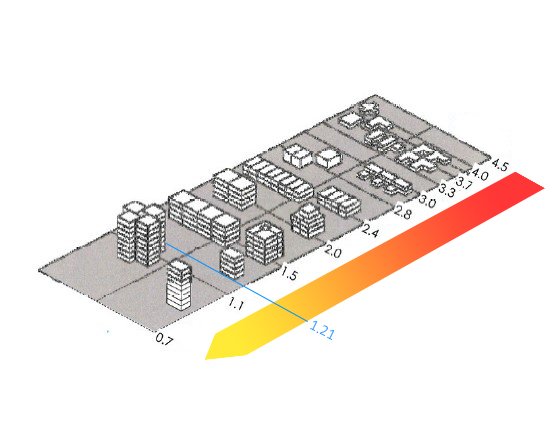

Form factor and Layout

An effective building shape and layout and clever configuration of openings in terms of both orientation and sizing minimise unnecessary energy losses from the outset. This was investigated at an early stage, testing design options to arrive at the most effective solution for the client. A rationalised building layout enabled us to achieve a good form heat loss factor of 1.21, significantly less than the target limit of 3 set by Passivhaus, reducing the effective insulation thickness required to maintain internal thermal comfort.

Fabric First Approach

Integrating Passivhaus knowledge into the design process allows for building systems to be designed in distinct zones, minimising penetrations, and creating an efficient envelope.

At the IDRM, this thinking was used to incorporate triple glazed windows (U-Value 0.6 W/m²K) which were carefully configured to minimise heat losses/gains, incorporating brise soleil to the east and west elevations and balancing these against the aspiration of the user group for optimal views out and openness.

The envelope was designed with a strong strategy to separate services, structure, insulation and cladding zones with a mineral wool composite panel system used as a wall substrate aimed at reducing thermal bridging (the cladding carrier system was supported from the outer sheet only, not breaching the insulation zone).

In addition, the building was designed to achieve Passivhaus levels of air tightness utilising a composite panel interlocking joint system to achieve this. At Construction stage, design workshops were held alongside McLaughlin & Harvey (Main Contractor), Stothers (M&E Contractor), Britplas (Envelope Contractor) and QODA (Sustainability Consultant) which focussed on reviewing additional measures and tricky details, as well as reducing penetrations through the building envelope. Where necessary, specialist products were sourced to reduce the risk of air leakage. On-site tests indicate this careful process, from detailing to expert workmanship, achieved an air tightness of 0.48 ACH50, which exceeds the 0.6 ACH50 required by the rigorous Passivhaus standards.

Mechanical Ventilation and Heat Recovery (MVHR)

Once energy inputs had been reduced to a minimum with an efficient layout and envelope, building comfort was ensured with the integration of an MVHR system, circulating fresh air throughout the building and recycling any residual heat from extract air to reduce heat losses due to leakage. In spite of the high ventilation requirements in the laboratory building, the M&E designers specified systems which were demand controlled and linked to air quality sensors to modulate flow rates between spaces in the most energy efficient manner.

Although not seeking full Passivhaus accreditation, at the IDRM we were able to design using this Passivhaus methodology, incorporating many of the advantages of Passivhaus for little over an estimated 1% cost uplift, a great example of a how a client first approach of focussing on the principles of Passivhaus helps to make improved energy performance in operation and the overall comfort of building users deliverable.

For more information on the project please take a further look here:

Institute of Developmental and Regenerative Medicine (IDRM) — SRA Architects (sra-architects.co.uk)